BSTI uses a science-based approach to close a site with LNAPL, save our client money and re-start a stalled real estate transaction.

The Problem

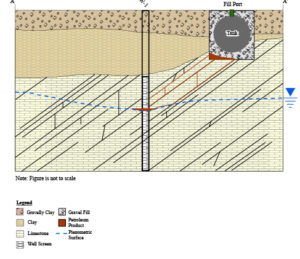

A release from a 30,000-gallon underground storage tank resulted in a body of diesel fuel above and below the water table (commonly referred to as light non-aqueous phase liquid or LNAPL). This condition created a regulatory compliance problem, a financial burden on the property owner and severely complicated a planned real estate transaction.

Based on a thorough site characterization, BSTI determined that potential mobility of the LNAPL body would be the primary driver to achieving closure with the regulatory agency. A traditional approach was first adopted that used a product recovery pump to actively remove available LNAPL from the subsurface. During the recovery process, BSTI tracked recovery rates, in-well liquid levels, and assessed the efficacy of the system. After several months, diminished returns of product recovery had been established and dissolved contaminants in groundwater remained below screening criteria at downgradient and perimeter monitoring wells. Despite establishing a technical argument for the cessation of LNAPL recovery, the regulator initially requested that additional recovery efforts be deployed based on an antiquated and unscientific “rule of thumb” cleanup criteria of reducing LNAPL thickness to less than 1-inch. LNAPL thickness has been the prevailing regulatory criteria for the past five decades and remains the closure criteria on the majority of LNAPL cleanup projects.

The Solution

Rather than accede to the regulator’s request for additional LNAPL remedial measures, BSTI employed a science-based approach to clearly establish that the LNAPL remaining at the Site presented an insignificant exposure risk to human health and the environment. Using data collected from the site, as well as following recently developed technical guidance (1), BSTI developed a sound LNAPL conceptual site model (LCSM). The LCSM utilized multiple lines of evidence, including a LNAPL Transmissivity analysis, showing that recovery efforts had indeed reached the point of diminished returns and additional remedial efforts were unlikely to appreciably diminish the remaining LNAPL body at the site. Moreover, an exposure pathway analysis revealed no direct link between the LNAPL and potential receptors. Through the development of a LCSM for the site, BSTI demonstrated an acceptable level of risk for the LNAPL remaining at the site which would avoid a potentially costly and enduring process of continuing to apply additional remedial measures.

BSTI’s request for closure was approved by the regulator and liability relief was granted to the client.

Benefits to the Customer

By avoiding the additional active remediation at the site, BSTI saved its client from venturing into a costly cleanup with an unclear endpoint. Due to the scientific demonstration of a non-mobile LNAPL body at the site and the low levels of dissolved COCs in groundwater, the site was able to be closed by attaining generic cleanup standards. As a result, the client was relieved of adherence to a long-term care and monitoring plan, a deed restriction, or an environmental covenant. The planned sale of the property took place without lingering environmental concerns.

For more information, contact Tripp Fischer at tfischer@bstiweb.com .

- (1) The Pennsylvania Department of Environmental Protection’s Revised Land Recycling Program Technical Guidance Manual (TGM) was finalized on January 19, 2019. The TGM provides guidance for implementing the Chapter 250 regulations promulgated pursuant to the Land Recycling and Environmental Remediation Standards Act (Act 2 of 1995). The current TGM includes valuable guidance on defining the removal of LNAPL to the Maximum Extent Practicable (MEP). The LNAPL guidance in the TGM is based in large part on the Interstate Technology & Regulatory Council’s (ITRC) LNAPL Team publications and trainings (https://www.itrcweb.org/Team/Public?TeamID=18) ASTM’s LNAPL Transmissivity Guidance (E2856), and ASTM LCSM Guide (E2531). BSTI’s Vice President and Principal Hydrogeologist Tripp Fischer, P.G. served as co-chair on this ITRC committee, is a trainer for the ASTM LNAPL Transmissivity Standard, and continues to provide training to regulatory bodies on the topic.