Brownfield Science & Technology, Inc. (BSTI) was retained by a lead consultant to assist in the operations and maintenance of an Accelerated In-Situ Bioremediation system (AISB) designed to address chlorinated solvent impacts in fractured bedrock at a Superfund site in Pennsylvania.

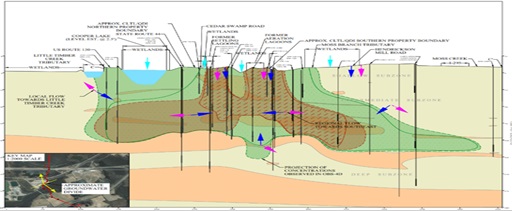

The primary objectives of the AISB system is to reduce the extent of the existing plume in the source area by a process known as reductive dechlorination, prevent further offsite migration and ultimately reduce the remaining dissolved phase mass by natural attenuation. To facilitate enhanced reductive dechlorination, reducing conditions are necessary such that the chlorinated VOCs (electron acceptors) are not in competition with naturally occurring electron acceptors (e.g., oxygen). To achieve these goals, groundwater is being extracted, amended with nutrients and reinjected into the aquifer to create an ideal environment for the microbes to grow and establish an in-situ dechlorinating bacterial treatment zone.

The AISB system had been operating for several years with diminishing returns. BSTI worked seamlessly with the lead consultant to identify operational inefficiencies and make recommendations to optimize the system. BSTI reconditioned the extraction and injection wells to provide for better communication between the wells and the aquifer. Upon rehabilitation of the injection/extraction wells, a series of pump tests were conducted to determine which wells should remain operational as extraction wells or converted to injection wells (or vise-versa). Lastly, a modification to the treatment amendments were completed to minimize fouling of the injection wells and promote for better distribution of the conditioned water into the aquifer.

BSTI’s operations of the system has since resulted in a significant increase in extraction/injection flow rates and a marked reduction in the groundwater impacts all while reducing operational costs and maintaining a >95 % operational uptime.