Client: Coal-fired Electrical Generating Station, Millsboro, DE

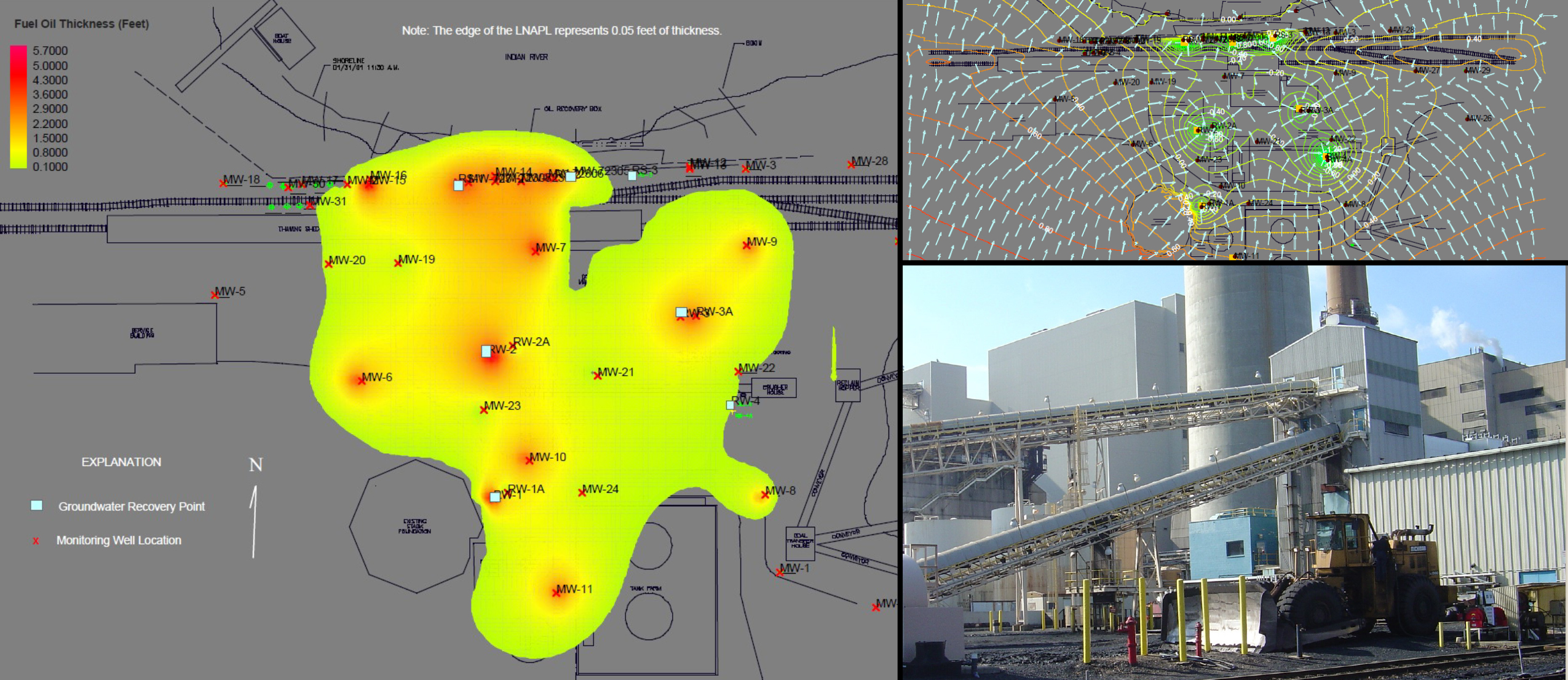

Brownfield Science & Technology, Inc. (BSTI) was retained to manage and implement remedial activities associated with a 500,000 gallon subsurface diesel fuel (LNAPL) spill at an operating electrical generating facility. The fuel spill adversely impacted on-site soil and groundwater and the sediments of an adjacent navigable marine estuary.

Within five months of spill discovery, BSTI had the first phases of a recovery system installed and operating. The main components of the strategy were four large-diameter groundwater pumping wells, high-volume LNAPL recovery skimming pumps and a central control center. The use of variable frequency drive groundwater pumps allowed for precise and consistent water table control in the tidally-influenced aquifer. Further, custom biocides and anti-fouling agents were used in each recovery well to the great benefit of system operation and up-time.

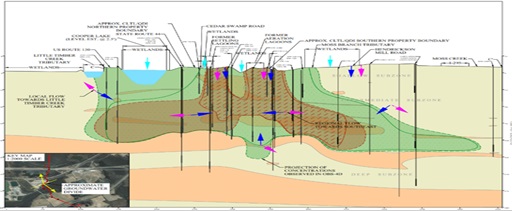

The ecological sensitivity of the adjacent marine estuary necessitated a supplemental and aggressive remedial approach. BSTI designed and installed a 54 point dual-phase extraction system along the banks of the estuary. Additional measures along the waterfront included in-situ oxidation treatments, excavation and vegetative restoration.

System-wide LNAPL recovery rates within the first year averaged 18,000 gallons per month. To eliminate off-site disposal, BSTI designed and installed a filtration and conditioning system to provide for the on-site reuse of recovered LNAPL.

BSTI provided operations and maintenance for all systems. Over the 14-year operational time span, the combined remediation systems averaged 95% up-time. Total LNAPL recovery is estimated to be 380,000 gallons.

In 2015, with the added support of a BSTI-generated fate and transport model, remedial and regulatory objectives were met and all systems were removed.