Brownfield Science & Technology, Inc. (BSTI), was hired to coordinate site construction and environmental monitoring activities pursuant to the terms of remedial actions on a contaminated site as defined by the USEPA’s Record of Decision.

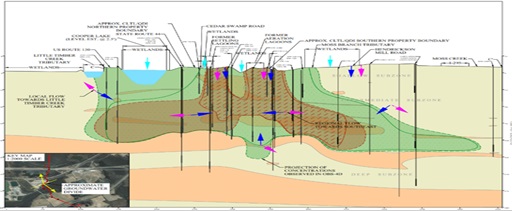

The remediation project utilized Electro Resistive Heating – Multi Phase Extraction (ERH-MPE) technologies designed to recover chlorinated volatile organic compounds (CVOCs) from a shallow wetland environment on a Superfund Site. BSTI provided logistical and technical support to the project team and facilitated the flow of information between site contractors, the client and USEPA officials.

BSTI managed a wide range of significant responsibilities, including; health and safety oversight, air monitoring, vapor cap integrity inspections and maintenance, management and coordination of hazardous waste disposal, technical assistance with ERH-MPE system operations, coordination and collection of all treatment system vapor and water sampling, and providing oversight for subcontractors hired to deconstruct, decontaminate and demobilize ERH-MPE system equipment.

BSTI played a key role in a collaborative effort to guide daily system operations through unforeseen obstacles to maintain proper system operations. The project team relied on BSTI’s skills acquired from years of experience with operations and maintenance on a wide variety of remediation systems to successfully troubleshoot technical problems and optimize the MPE treatment system functions.

The highest priority was placed on insuring the health and safety of workers and the surrounding community. BSTI performed extensive daily air monitoring within and surrounding the treatment areas, screening for fugitive vapor emissions by utilizing a PID and detecting for vinyl chloride with colorimetric gas detector tubes. Any detections above the limits defined in the Site Health & Safety Plan resulted in immediate and appropriate action to restore system integrity and safe working conditions.

BSTI managed all aspects of the project’s comprehensive and fast paced sampling program by collecting all MPE system samples, coordinating all sampling activities with multiple analytical laboratories and maintaining the sampling supplies and equipment inventories. BSTI developed safe sampling procedures and fabricated specialized sampling systems for the collection of “HOT” TO-15 and TO-13 vapor samples.

All wastes that were generated through the various phases of the project had to be characterized for disposal profiling, handled properly, placed into appropriate holding vessels, stored in proper containment systems and safely loaded onto certified waste handler vehicles for disposal. BSTI successfully managed every step of the waste management process which included hazardous materials containing PCB’s.

In order to facilitate the exchange of up to date information for this dynamic project, BSTI conducted daily site meetings with USACE representatives where system performance, operations and maintenance, sampling schedules and health and safety issues were discussed in detail. Waste generation logs, sampling logs and field reports were maintained and issued daily to project team leaders and our client.